Handpan ua yog ntau tshaj li "tso tawm lub tais." Nws yog cov txheej txheem ntev, ua tib zoo saib nrog qhov tsis ua haujlwm siab, feem ntau xav tau tus tsim kom mob siab rau kaum ob lossis ntau pua teev. Cov txheej txheem tuaj yeem muab faib ua cov theem tseem ceeb hauv qab no:

Theem 1: Tsim & Xaiv cov khoom siv

Qhov Tseem Ceeb Tsim: Ua ntej pib, tus tsim yuav tsum xub txiav txim siab tus yuam sij ntawm tes (xws li D Kurd, C Arabian, thiab lwm yam). Qhov no txiav txim siab qhov tseem ceeb ntawm lub hauv paus ding note thiab kev npaj thiab kev sib raug zoo ntawm cov ntawv nyob ib puag ncig (Tone Fields).

Kev xaiv hlau: Cov khoom siv tes ua tseem ceeb feem ntau yog tsim los ntawm ob hom hlau:

Nitrided Steel: Qhov no yog cov khoom siv feem ntau thiab muaj kev saib xyuas zoo. Nws yog ib qho nyuaj heev thiab corrosion-resistant, ua ib lub suab kaj, ntev ntev uas nplua nuj nyob rau hauv overtones. Cov neeg sawv cev hom muaj xws li PANAart (tus tsim ntawm Hang).

Stainless Hlau: Yooj yim rau kev ua haujlwm nrog, nws feem ntau ua rau lub suab sov, softer nrog ib qho kev lwj me ntsis. Ntau lub tuam txhab ua lag luam kuj tseem siv stainless hlau.

Txiav: Cov phaj loj loj uas xaiv yog plasma-txiav lossis laser-txiav rau hauv ib lub voj voog.

Theem 2: Shaping

Hydraulic Pressing: Lub tiaj tiaj tiaj tiaj yog muab tso rau ntawm cov pwm thiab nias rau hauv lub cim "flying saucer" zoo li siv lub xovxwm hydraulic loj, tsim cov qauv pib ntawm sab sauv (Ding) thiab qis (Gu) plhaub.

Tes Hammering: Qhov no yog txoj hauv kev zoo tshaj plaws thiab kev kos duab (tseem siv los ntawm PANAart). Tus kws tsim khoom siv dag zog tag nrho ntawm kev paub thiab kev xav, hammering lub billet rau hauv qhov kawg dome duab me ntsis los ntawm me ntsis. Txoj kev no muab txhua tus tes tuav nws tus cwj pwm tshwj xeeb.

Theem 3: Tone Field Layout & Initial Tuning

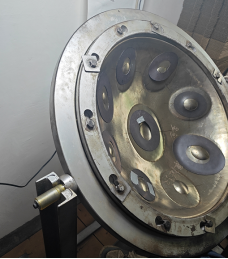

Kos lub Tone Fields: Nyob rau ntawm lub dome ntawm lub plhaub sab sauv, cov haujlwm thiab cov duab ntawm lub hauv paus Ding thiab ib puag ncig 7-8 lub suab teb tau raug cim raws li qhov tsim kho.

Rauj: Siv hammers ntawm ntau yam duab thiab cov hlau saum toj kawg nkaus, qhov chaw cim yog indented los ntawm hammering, tsim qhov pib suab ntau yam. Qhov tob, zoo, thiab curvature ntawm txhua qhov indentation cuam tshuam lub suab kawg thiab cov ntoo.

Kauj Ruam 4: Kev Kho Kom Zoo - Cov Ntsiab Lus Tseem Ceeb thiab Cov kauj ruam nyuaj tshaj plaws

Qhov no yog qhov xav tau tshaj plaws ntawm cov txheej txheem tsim khoom, xav tau tus tsim kev txawj ntse thiab pob ntseg, siv sijhawm ntev tshaj plaws thiab muaj qhov ua tsis tau zoo tshaj plaws. Tuning tsis ua los ntawm zawm screws; es, hammering yog ua los hloov cov hlau sab hauv kev ntxhov siab, yog li hloov nws lub suab.

Normalizing: Tom qab pib tsim, lub plhaub hlau tau dhau los ua qhov tseem ceeb hauv kev ntxhov siab vim yog hammering, ua rau nws nyuaj thiab nkig. Lub tshuab ua kom sov rau qhov kub thiab txias (kwv yees li 800-900 ° C) thiab tom qab ntawd maj mam txias nws kom txo tau qhov kev ntxhov siab thiab ua kom cov hlau muag muag, npaj nws rau qhov zoo tom ntej.

Rauj Tuning:

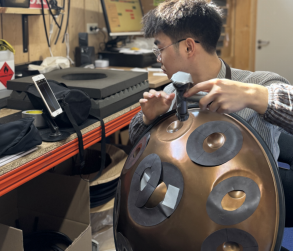

Tus neeg tsim khoom ruaj ntseg lub plhaub rau ib qho chaw ua haujlwm siab, ntes lub suab ntawm txhua daim ntawv nrog lub microphone soj ntsuam, thiab tshuaj xyuas nws cov zaus zaus thiab overtone series siv spectrum tsom xam software.

Lawv siv tshwj xeeb crafted me hammers rau ntaus heev maj mam ntawm tej qhov chaw nyob rau hauv lub register.

Strikes nyob rau hauv nruab nrab ntawm lub register (lub crown) feem ntau txo lub suab.

Strikes ntawm ntug ntawm lub register (lub xub pwg nyom) feem ntau tsa lub suab.

Cov txheej txheem no yuav tsum muaj ntau txhiab lub voj voog rov ua kom zoo. Lub hom phiaj tsis yog tsuas yog los xyuas kom meej lub suab nrov ntawm txhua qhov kev sau npe yog qhov tseeb, tab sis kuj kom ntseeg tau tias nws cov overtones yog dawb huv, nplua nuj, thiab muaj kev sib haum xeeb ntawm kev sau npe. Ib tug zoo tsim tunes tsis yog ib tug neeg sau ntawv, tab sis tag nrho cov twj paj nruag soundstage thiab resonance.

Theem 5: Sib dhos & Kev Kho Mob Kawg

Gluing: Lub plhaub sab sauv thiab sab qis yog sib koom ua ke, feem ntau yog siv cov kua nplaum uas muaj zog epoxy. Lub foob thiab lub zog ntawm daim ntawv cog lus yog qhov tseem ceeb, cuam tshuam rau resonance thiab durability.

Nitriding (yog tias siv cov hlau nitrided): Lub lauj kaub sib dhos tau muab tso rau hauv lub qhov cub tshwj xeeb thiab cov roj nitrogen tau nkag rau ntawm qhov kub thiab txias. Nitrogen atoms nkag mus rau hauv cov hlau, ua ib qho nyuaj heev thiab hnav-resistant nitride txheej. Cov txheej txheem no thaum kawg xauv hauv lub suab, uas yuav NW nyuam qhuav hloov nrog kev tawm tsam tom ntej. Qhov no yog vim li cas nitrided steel lauj kaub thiaj li ruaj khov thiab ruaj khov.

Tiav: Qhov saum npoo yog ntxuav, polished, los yog muaj hnub nyoog los muab nws qhov kawg tsos.

Kev Tswjhwm Zoo Kawg: Lub panmaker ua qhov kawg, ua tib zoo tshuaj xyuas ntawm qhov ntsuas lub suab, lub suab, qhov tsos, thiab xav kom nws ua tau raws li lub Hoobkas.

Raysen handpan ua txheej txheem:

https://youtu.be/H7Fd4OWj-cY?si=rWPfis2RbCEMpZDq

Yav dhau los: Txais tos tuaj xyuas peb ntawm JMX Show 2025!